Tablet Hardness Tester

Tablet Hardness Tester Specification

- Resolution

- 0.01 kg

- Response Time

- Instantaneous

- Operating Voltage

- 230 V AC, 50 Hz

- Equipment Type

- Tablet Hardness Tester

- Application

- To test tablet crushing strength (hardness)

- Max Height

- Approx. 300 mm

- Humidity

- 20% - 80% RH

- Accuracy

- 0.5% F.S.

- Test Range

- 2 20 mm (tablets)

- Display Type

- Digital LCD

- Frequency

- 50 Hz

- Number of Specimens

- One tablet at a time

- Features

- LED display, accurate measurement, robust body

- Interface Type

- Digital interface

- Temperature

- 10C 40C

- Hardness

- Test up to 500 Newtons

- Power Supply

- 230 V AC, 50 Hz

- Automation Grade

- Manual/Semi-Automatic

- Mounting Type

- Bench-Top

- Specimen Size

- 2 20 mm

- Measuring Range

- 0 - 20 kg

- Usage

- Pharmaceutical Laboratory Testing

- Capacity

- Up to 500 N

- Machine Weight

- 5 kg

- Test Speed

- Adjustable upto 60 tablets/hour

- Test Width

- Standard for pharmaceutical tablets

- Test Stroke

- Up to 20 mm

- Control Mode

- Manual / Digital

- Operation Environment

- Laboratory indoor

- Safety

- Overload protection

- Accessories

- User Manual, Power Cord

- Finish

- Powder Coat / Polished

- Storage Condition

- Store in dry and cool place

- Tablet Types Accepted

- Round, Oblong, Oval

- Complies with Standards

- USP, EP & IP

- Measurement Unit

- Newton and Kilogram

- Body Material

- Stainless Steel

- Calibration

- Provided with Calibration Certificate

About Tablet Hardness Tester

Tablet Hardness Tester

Tablet Hardness Tester is a lab technique, utilized by pharmaceutical industry for determining the structural integrity as well as breaking point of the tablets. Its utilization ensures that the tablets are hard enough to uphold the mechanical strains and keep them for long time. As there is a possibility of tablet breaking during storage, delivery, or packaging, handling etc. Tablet Hardness Tester is apt to detect the disintegration of tablet, if any. This is proffered with excessive bonding possibilities and has the capacity to make control on the production process. The said testing equipment is popular as a proven, reliable and most accurate method.

High Precision & Versatile Testing

Accommodating a variety of tablet shapes and sizes, this tester operates within a 220 mm range with capacity up to 500 Newtons or 20 kg force. The digital LCD delivers immediate, precise readings, while adjustable test speeds up to 60 tablets per hour enhance workflow. Rigorously compliant with USP, EP, and IP standards, it is ideal for rigorous quality control in pharmaceutical labs.

Built for Laboratory Durability & Safety

Fabricated from stainless steel and finished for corrosion resistance, this testers robust construction ensures longevity even under frequent use. Overload protection provides essential safety for operators, and all units include a calibration certificate, user manual, and power cord for straightforward installation. Store the device in cool, dry environments to maintain optimal accuracy and performance.

FAQs of Tablet Hardness Tester:

Q: How do I operate the Tablet Hardness Tester for accurate results?

A: Begin by selecting the desired control mode (manual or digital), then place a single tablet (220 mm) in the test groove. Set the test speed and stroke as required, and initiate the test. The hardness will be displayed instantly on the digital LCD in Newtons or kilograms. Refer to the user manual for detailed operating instructions.Q: What types of tablets can this device test?

A: The tester accommodates round, oblong, and oval tablets within a 220 mm size range, making it suitable for most pharmaceutical tablet forms. It is engineered specifically for applications demanding high accuracy in diverse tablet types.Q: When is calibration required and is a certificate provided?

A: Calibration ensures the devices measurement accuracy and should be performed regularly per laboratory protocols or when indicated by regulatory standards. This tester comes with a calibration certificate for compliance and quality assurance needs.Q: Where should the Tablet Hardness Tester be installed and stored?

A: Install the device on a laboratory bench-top in an indoor environment with controlled temperature (10C 40C) and humidity (20%80% RH). After use, store it in a dry, cool location to protect its sensitive components and uphold measurement precision.Q: What is the process if the tablet hardness exceeds the testers capacity?

A: If a tablet requires more than 500 Newtons, the devices overload protection feature will activate to prevent damage. Always ensure tablets to be tested fall within the specified hardness capacity to maintain equipment integrity.Q: How can I benefit from using this hardness tester in a pharmaceutical lab?

A: This device provides instant, precise hardness measurements, supporting robust quality control for tablet production. Its compliance with international standards (USP, EP, IP) and durable stainless steel build ensure reliability and facilitate regulatory audits, ultimately enhancing product consistency and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Testing Instruments Category

DIGITAL FRIABILITY TEST APPARATUS

Minimum Order Quantity : 1 Piece

Usage : Pharmaceutical Laboratory Testing

Application : Tablet/Capsule Friability Testing

Power Supply : 230V 10% AC, 50 Hz

Features : Programmable Timer, Automatic drum stop, Audible alarm on test completion

Resolution : 1 Revolution

E.C.G. Machine

Usage : Hospital, Clinic, Diagnostic Center

Application : Cardiac diagnostic / Patient monitoring

Power Supply : 220V / 50Hz AC or builtin rechargeable battery

Features : Thermal printer, Digital filters, Leadoff detection, Rechargeable battery

Resolution : 12 bit

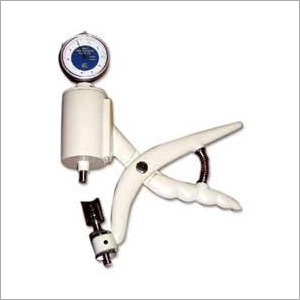

Pfizer Type Tablet Hardness Tester

Usage : Pharmaceutical laboratory, tablet production QA

Application : Measuring breaking point or hardness of tablets

Power Supply : Not Required (Manual)

Features : Lightweight, portable, easy to handle, robust metal construction

Resolution : 0.1 kg

Digital TDS Meter

Usage : Measuring Total Dissolved Solids in Water

Application : Water Purity Testing

Power Supply : 2 x 1.5V LR44 Button Cell Batteries

Features : Hold Function, Automatic Temperature Compensation (ATC), Autooff, Low Battery Indicator

Resolution : 1 ppm

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS