Cleaveland Flash Point and Fire Point Apparatus

Cleaveland Flash Point and Fire Point Apparatus Specification

- Mounting Type

- Bench-top

- Humidity

- Up to 80% RH (non-condensing)

- Port Size

- Standard size for burner port

- Display Type

- Analog or dial thermometer

- Measuring Range

- Ambient to 370C

- Number of Specimens

- Single specimen

- Resolution

- 1C

- Automation Grade

- Manual

- Specimen Size

- 75 ml (standard test cup)

- Frequency

- 50 Hz

- Max Height

- Approx. 350 mm

- Power Supply

- 230 V, 50 Hz AC

- Response Time

- Immediate (manual observation)

- Application

- Determining flash and fire points of petroleum products

- Equipment Type

- Flash & Fire Point Apparatus

- Test Range

- Ambient to 370C

- Operating Voltage

- 230 V AC

- Temperature

- Ambient to 370C

- Gas Pressure

- Atmospheric or as recommended

- Accuracy

- 1C

- Features

- Heavy-gauge brass cup, energy regulator, high quality insulation, manual flame application, flame exposure shutter

- Usage

- Laboratory/Testing Petroleum Products

- Capacity

- 75 ml cup

- Machine Weight

- Approx. 6.5 kg

- Test Speed

- Manual operation

- Test Width

- Standard: accommodates test cup

- Control Mode

- Manual

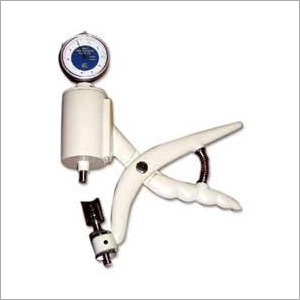

About Cleaveland Flash Point and Fire Point Apparatus

Cleaveland Flash Point & Fire Point Apparatus

Get in touch with us for this superior quality Cleaveland Flash Point & Fire Point Apparatus which is widely used for determining the flash point of various petroleum products. It comprises of heating plate, cup, swivel joint in order to pass over test liquid surface. Our offered component has simple features which allow smooth functioning and easy usage. Cleaveland Flash Point & Fire Point Apparatus has a rugged construction.

Advanced Heating and Safety Features

This apparatus incorporates a concealed electrical heater with a variable energy regulator for controlled temperature rise during tests. A heat-resistant handle, powder coated finish, and high-quality housing insulation ensure operator safety and equipment durability over extended usage.

Reliable and Precise Test Results

The brass test cup, insulated air bath, and manual stirring mechanism allow for precise, repeatable measurement of flash and fire points. The analog or dial thermometer delivers accurate readings up to 400C (depending on the supplied thermometer), ensuring reliable data for petroleum testing laboratories.

User-Friendly, Manual Operation

Engineered for simplified/manual use, the apparatus includes a stable bench-top mounting and an easy-to-remove cup for specimen changeover. The process accommodates one 75 ml sample per test using a hand-operated stirring system and an atmospheric-pressure burner port for natural gas or LPG.

FAQs of Cleaveland Flash Point and Fire Point Apparatus:

Q: How does the Cleaveland Flash Point and Fire Point Apparatus determine the flash and fire points of petroleum products?

A: The apparatus heats a petroleum sample in a brass test cup using a concealed electrical heater. As the temperature rises, a gas flame is periodically applied to the samples surface. The flash point is the lowest temperature at which vapors ignite momentarily, while the fire point is when sustained burning occurs. Observations are made manually using the analog thermometer.Q: What materials are used in the construction of this apparatus, and why are they important?

A: The apparatus features a mild steel housing with heat-resistant insulation, a corrosion-resistant powder coated finish, a heavy-gauge brass test cup for durability, and a cast iron air bath for even heat distribution. These high-quality materials enhance safety, longevity, and reliability.Q: When should I use the Cleaveland Apparatus, and for what applications is it best suited?

A: This apparatus is ideal for laboratory testing, exporter quality checks, and manufacturer compliance when determining the flash and fire points of petroleum products as per standard protocols. It is suitable whenever accurate measurement of petroleum volatility and combustion properties is required.Q: Where can the apparatus be installed and used most effectively?

A: The apparatus is designed for bench-top installation in laboratories, research centers, and quality control facilities. Its compact dimensions and manual operation make it suitable for standard laboratory environments with ambient humidity up to 80% RH.Q: What is the process for conducting a test using this apparatus?

A: Fill the brass test cup with a 75 ml sample, set up the concealed electrical heater, and regulate temperature using the energy regulator. Stir the sample manually while observing the thermometer. At intervals, introduce the test flame via the burner port to detect flash and fire points.Q: How does manual operation benefit the user during testing?

A: Manual operation grants the user direct control over stirring, heat application, and timing, ensuring precision and adaptability to specific testing needs. Immediate observation of results allows for quick decision-making and enhances process reliability.Q: What are the main advantages of using this apparatus for flash and fire point determination?

A: Key benefits include precise temperature control (accuracy 1C), durable construction, easy specimen handling, adaptability to different fuels (natural gas or LPG), and compliance with laboratory testing standards, ensuring dependable and repeatable results in petroleum analysis.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Testing Instruments Category

Tablet Hardness Tester

Mounting Type : BenchTop

Humidity : 20% 80% RH

Usage : Pharmaceutical Laboratory Testing

Control Mode : Manual / Digital

Automation Grade : Manual/SemiAutomatic

Resolution : 0.01 kg

Spectrophotometer

Mounting Type : Benchtop

Humidity : 80% RH (noncondensing)

Usage : Spectral analysis of liquid samples

Control Mode : Manual / Digital

Automation Grade : SemiAutomatic

Resolution : 0.1 nm

Pfizer Type Tablet Hardness Tester

Mounting Type : Handheld

Humidity : Up to 85% RH (NonCondensing)

Usage : Pharmaceutical laboratory, tablet production QA

Control Mode : Hand Operated

Automation Grade : Manual

Resolution : 0.1 kg

Falling Ball Viscometer

Mounting Type : Benchtop

Humidity : Up to 90% RH noncondensing

Usage : Laboratory analysis of viscosity

Control Mode : Manual

Automation Grade : Manual

Resolution : 0.01 mPas

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free