Suppository Moulds

Suppository Moulds Specification

- Material

- Aluminium with Nickel Plating

- Condition

- New

- Technology

- Conventional Moulding

- Portable

- Yes

- Disposable

- No

- Wall Mounted

- No

- Measurement

- Suppository size: commonly 1 gm, 2 gm, 3 gm, 5 gm etc.

- Operating Type

- Manual

- Size

- Standard sizes as per capacity, available in different cavity counts

- Weight

- Lightweight, varies by cavity count

- Color

- Metallic Silver

- Attributes

- Reusable, Easy to clean, Precision construction

- Usage

- Pharmaceutical formulation of suppositories

- Temperature Resistance

- Withstands standard melting and cooling cycles for suppository production

- Packaging

- Individual set in protective box

- Sterility

- Can be autoclaved for hygienic use

- Manufacturing Standard

- Manufactured under GMP conditions

- Closure Type

- Screw type or tight fit clamps

- Compatibility

- Suitable for glycerin, cocoa butter, PEG base formulations

- Finish

- Highly polished surface for easy mould release

- Cavity Count

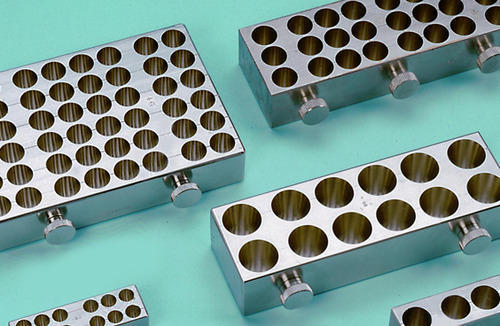

- Available in 6, 12, or custom cavity configurations

Suppository Moulds Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Australia, South America, Western Europe, Middle East, Central America, Asia, Eastern Europe, North America, Africa

- Main Domestic Market

- All India

About Suppository Moulds

We are one of the leading manufacturers, suppliers, and exporters of Suppository Moulds that come in various shapes and sizes as per the order placed by our customers. It is manufactured by using premium quality stainless steel which is provided with a galvanized coat that helps in the prevention of rust and corrosion. It can be used in pharmaceutical as well as medical applications. Suppository Moulds availed by us allow direct localization for both internal and external hemorrhoids.Versatile Configurations and Precision Engineering

Our suppository moulds are available in standard 6 and 12 cavity counts or can be customized to your specific needs. Made from lightweight aluminium with nickel plating, these moulds offer exceptional durability and precise construction. Their metallic silver finish is both functional and visually appealing, ensuring a professional look for your laboratory or manufacturing facility.

Easy Release and Hygienic Operation

The highly polished surface of each mould ensures effortless suppository release, reducing waste and saving time during production. These moulds are designed for easy cleaning and can be autoclaved for enhanced sterility, making them an excellent choice for pharmaceutical operations that value hygiene and safety.

Broad Compatibility and User-Friendly Design

Our moulds are suitable for use with a wide range of suppository bases, including glycerin, cocoa butter, and PEG formulations. Portable, reusable, and supplied in a secure protective box, they integrate seamlessly into manual production workflows and meet rigorous GMP standards.

FAQs of Suppository Moulds:

Q: How are the suppository moulds cleaned and sterilized after use?

A: The moulds can be easily cleaned due to their highly polished nickel-plated aluminium surfaces. For hygienic use, they can be autoclaved, ensuring sterility before every production cycle.Q: What types of suppository formulations are compatible with these moulds?

A: These moulds are suitable for glycerin, cocoa butter, and PEG base formulations, making them versatile for various pharmaceutical applications.Q: When should I choose a mould with a specific cavity count?

A: Select the cavity count based on your batch size and production requirements. Standard options include 6 and 12 cavities, and custom configurations are also available for higher or specialized outputs.Q: Where can these suppository moulds be used?

A: They are ideal for use in pharmaceutical manufacturing facilities, research laboratories, and compounding pharmacies that produce suppositories for commercial or medical use.Q: What is the process for releasing suppositories from the mould?

A: After the suppository formulation cools and solidifies, the highly polished surface and screw-type or tight fit clamp closure ensure smooth and easy release without damaging the product.Q: What are the primary benefits of using these reusable moulds?

A: Key benefits include precision in suppository sizing, reusable and durable construction, compatibility with various bases, easy cleaning, and a hygienic design that meets GMP requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Laboratory Equipment Category

Laboratory Instruments Microscope

Size : 350mm x 220mm x 150mm (approximate)

Portable : Yes

Color : White & Black

Weight : Approx. 5 kg

Technology : Other, Optical Microscope

TLC Kit

Size : Standard TLC plate size: 20 x 20 cm or 10 x 10 cm; kit box size may vary

Portable : Yes

Color : Transparent (plates); assorted (kit box and accessories)

Weight : Lightweight; approx. 400600 grams (kit)

Technology : Other, Thin Layer Chromatography (TLC)

Ball Mill

Size : Variable (custom sizes available)

Portable : No

Color : Blue or as per client requirement

Weight : Variable (depends on model)

Technology : Other, Mechanical

Polarimeter Tube

Minimum Order Quantity : 1 Unit

Size : Available in standard lengths (typically 100 mm and 200 mm)

Portable : Yes

Color : Transparent / Clear

Weight : Lightweight

Technology : Other, Manual

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free